Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

30 Nov , 2025

Concrete Screws vs Concrete Anchors: Which Fastener Is Better for Masonry?

By Ferry International – India’s Leading Manufacturer & Exporter of Industrial Anchors & Fasteners

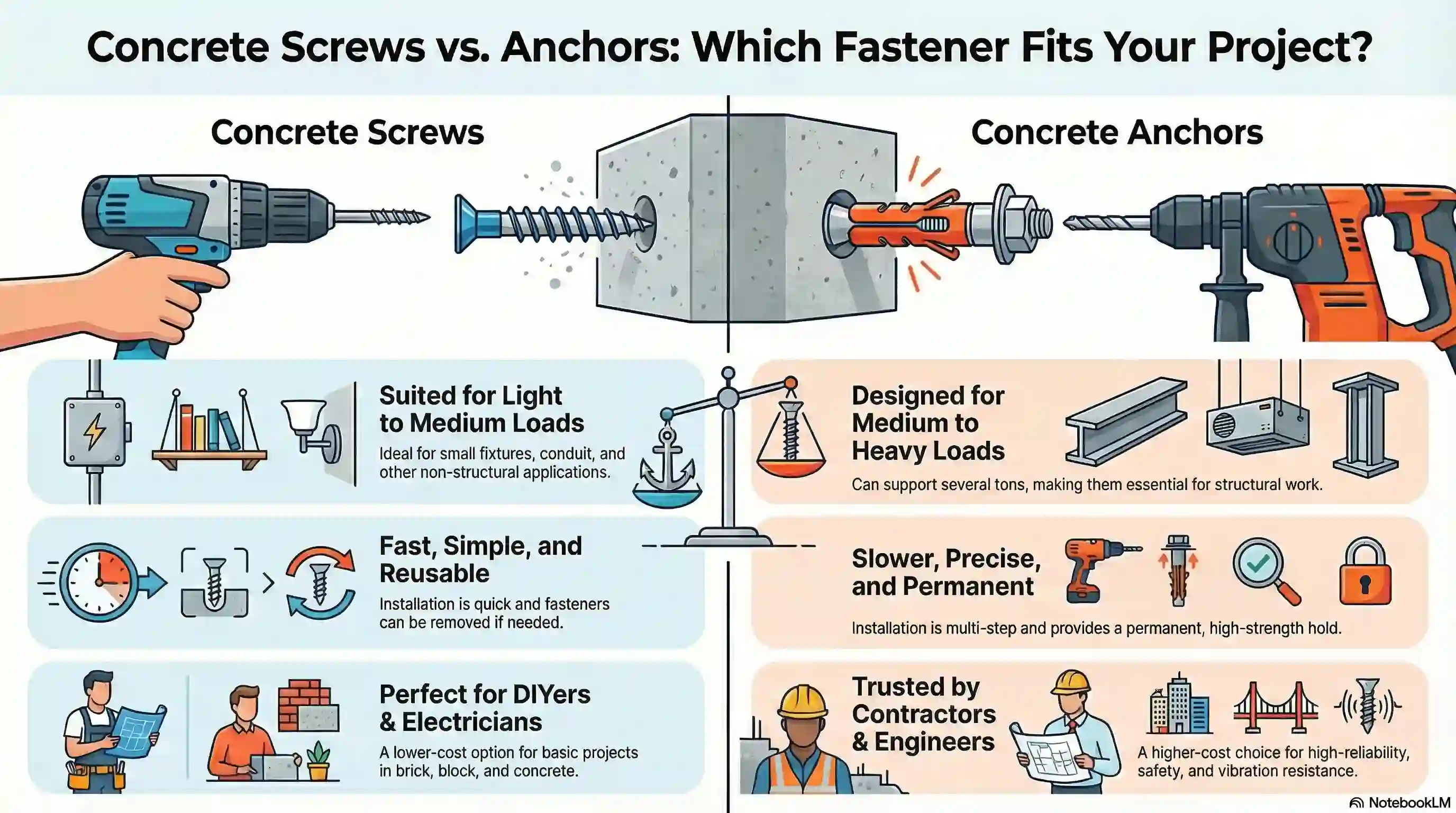

When working on masonry projects—whether in construction, industrial setups, solar installations, PEB structures, commercial interiors, or home repairs—the fastener you choose plays a major role in overall safety and performance. Two of the most commonly used solutions are concrete screws and concrete anchors.

Even though both are used to fix items into concrete, brick, or block, their:

They are completely different.

Selecting the wrong fastener can lead to loose fixtures, structural damage, equipment failures, and safety hazards. For contractors, engineers, builders, and project managers, understanding the difference is essential.

This detailed guide by Ferry International, a global manufacturer of industrial anchors and fasteners, explains everything you need to know about concrete screws vs. concrete anchors—and helps you choose the right one.

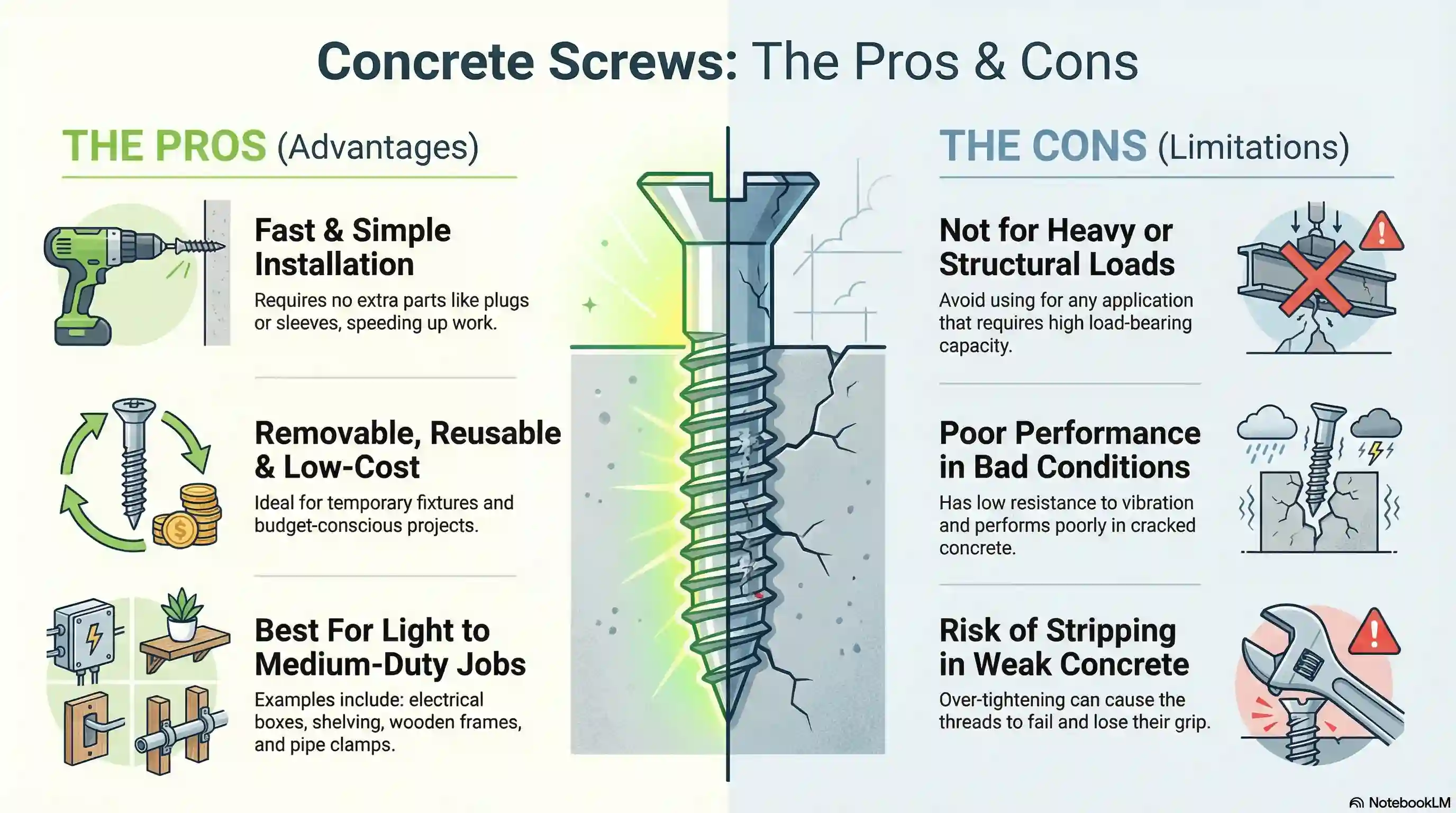

Concrete screws are self-tapping fasteners designed for light-to-medium duty fixings. They cut their own internal threads inside the material when inserted.

Their high–low threads bite into concrete when the screw is driven into the drilled hole. This creates friction and a strong but limited hold.

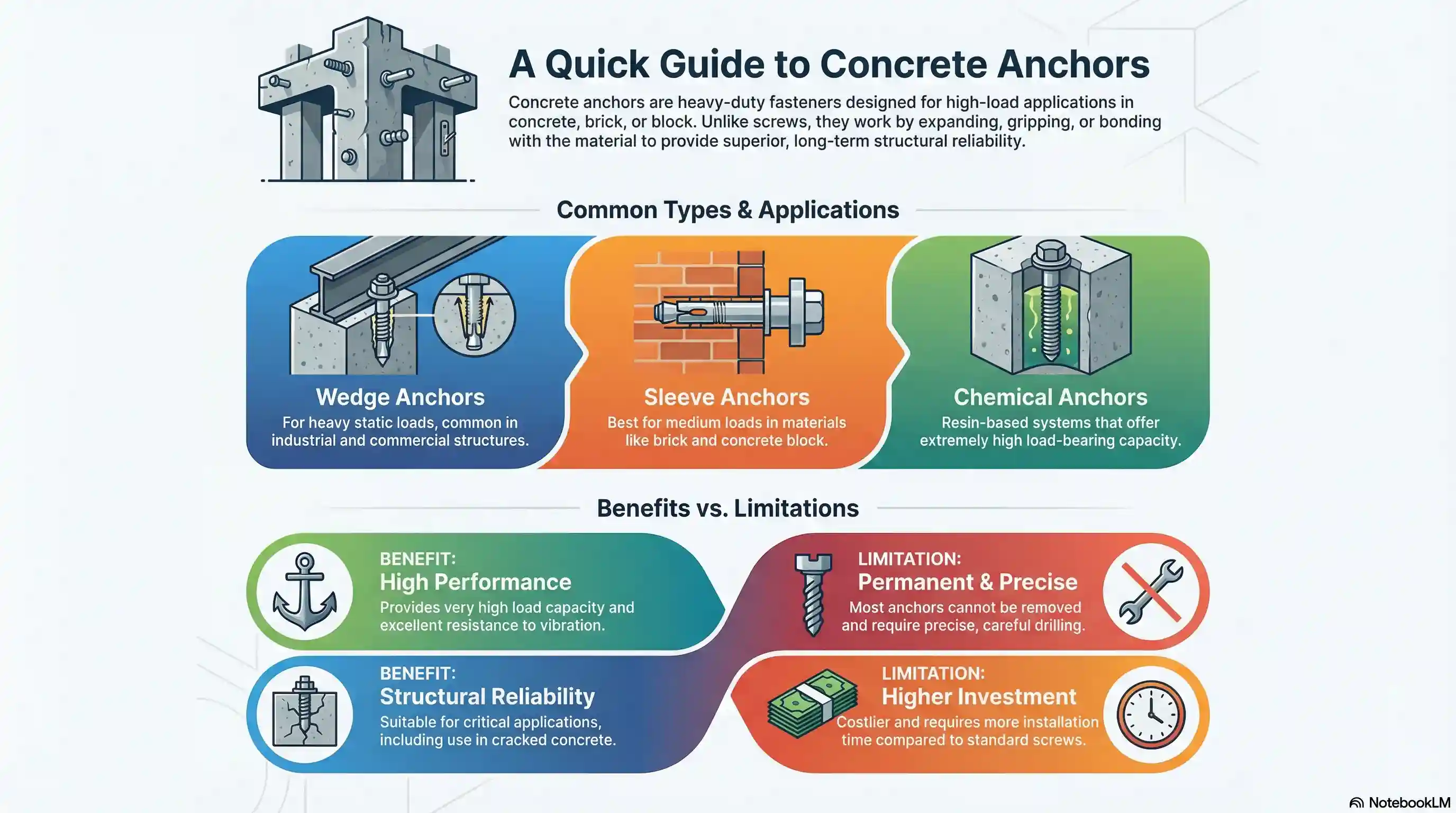

Concrete anchors are heavy-duty fastening systems designed for high load-bearing capacity and long-term performance. Unlike screws that rely on cutting threads, anchors work by expanding, gripping, or bonding inside the hole.

| Feature / Parameter | Concrete Screws | Concrete Anchors |

|---|---|---|

| Load Capacity | Light → Medium | Medium → Heavy (up to several tons) |

| Installation Speed | Very fast | Slower (more steps) |

| Reusability | Removable & reusable | Usually permanent |

| Drilling Requirement | Simple drilling | Precise drilling & cleaning |

| Vibration Resistance | Low | High (ideal for machinery) |

| Cost | Lower | Higher |

| Suitability in Cracked Concrete | Limited | Excellent (Chemical & Wedge Anchors) |

| Applications | Small fixtures, DIY | Industrial, structural, heavy-duty |

| Base Materials | Brick, block, concrete | Mainly concrete (cracked & uncracked) |

| Strength & Safety | Moderate | Very high & reliable |

| Ideal Users | Homeowners, electricians | Engineers, contractors, industrial users |

✔ Load is light

✔ Installation must be quick

✔ Fixture is temporary or removable

✔ Using brick or block

✔ Mounting small products

✔ Load is heavy

✔ Safety is critical

✔ Structure experiences vibration

✔ It’s an industrial or construction project

✔ Compliance with IS / ASTM standards is required

✔ Long-term performance is needed

HDG wedge anchors are preferred for module mounting structures.

✔ High wind load resistance

✔ Long-term durability

Drop-in anchors are used for suspended ducts and threaded rods.

✔ Strong overhead grip

✔ Vibration resistance

Chemical anchors or wedge anchors are used for pallet racks.

✔ High safety requirements

✔ Supports dynamic loading

Stainless steel wedge anchors / anchor bolts are used.

✔ Structural stability

✔ Shock and vibration resistance

Concrete screws for conduits, cable trays, boxes.

✔ Fast, economical, convenient

Using certified anchors ensures consistent and safe performance.

Concrete screws are best for small, quick, non-critical applications.

Concrete anchors are designed for heavy-duty, structural, and industrial purposes.

For any application where safety, load, or long-term performance matters, always choose concrete anchors.

Ferry International manufactures and supplies:

📞 Call/WhatsApp: +91 9990877399

🌐 Website: www.ferry-international.com

📩 Email: contact@ferry-international.com

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>